Capabilities

Quality

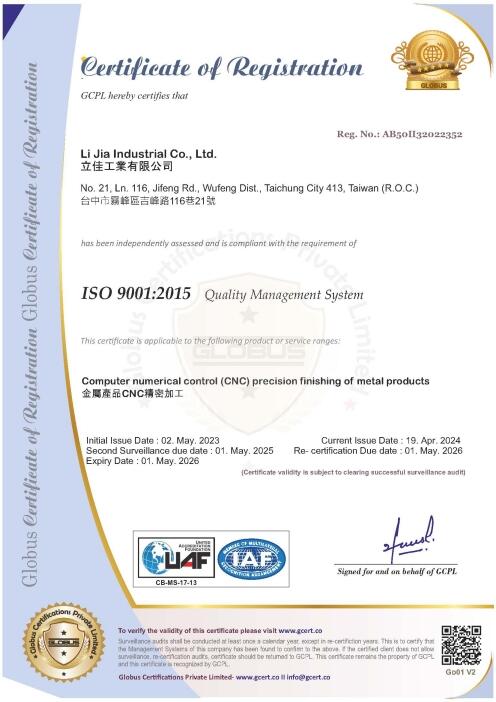

ISO 9001:2015 Certified

Quality Management & Benefits

- StandardProcess Standardization

Establish SOP manuals to ensure high stability and yield from programming to production.

- TraceabilityInstrument Precision

Precision instruments are calibrated by third parties to ensure data accuracy and credibility.

- InspectionInspection History System

Strictly implement traceability reports for "First-piece, In-process, Final" to ensure stability.

- ContinuityContinuous Improvement

Optimize processes via PDCA cycles and records to enhance customer cooperation and satisfaction.

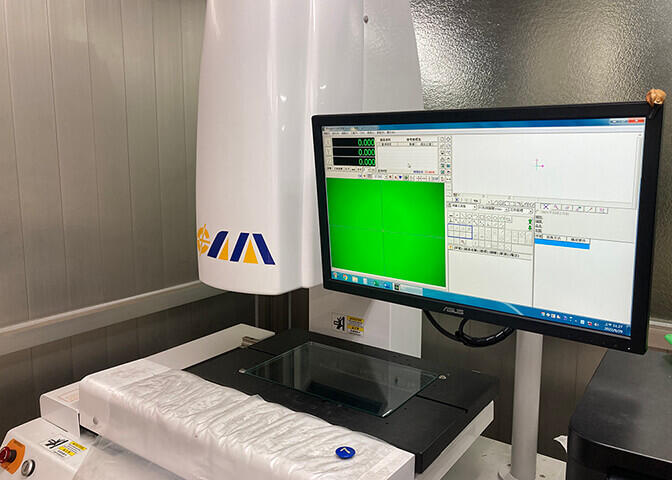

2.5D Automatic Vision Measuring System

Combines high-res optics with auto-recognition. Non-contact measurement captures precise dimensions, replacing manual checks for faster, more accurate, and stable mass inspection.

| Range (X/Y/Z) | 300x200x200mm |

|---|---|

| Lens Focal Length | Stepless Zoom (17.5X~112.5X) |

| Operation Mode | Fully Automatic |

| Repeatability | 0.003mm |

| Brand | ARCS Precision Technology |

Coordinate Measuring Machine (CMM)

Core equipment for precise 3D measurement. High-sensitivity probes capture geometry and tolerances, providing accurate data to ensure complex parts meet design specs.

| Range (X/Y/Z) | 500x400x400mm |

|---|---|

| Operation Mode | Manual |

| Repeatability | 0.003mm |

| Brand | Mitutoyo |

Handheld Bluetooth Measuring Tools

Integrates Bluetooth technology, covering calipers, height gauges, and micrometers. One-click data upload eliminates manual errors, reduces checking burden, and connects seamlessly to digital QC systems.

| Calipers | Accuracy 0.01mm |

|---|---|

| Height Gauge | Accuracy 0.001mm |

| Micrometer | Accuracy 0.001mm |

Various Standard Gauges

Complete set of block gauges, pin gauges, thread gauges (plug/ring), and radius gauges. All regularly calibrated to provide precise benchmarks from basic dimensions to complex threads, strictly controlling every detail.

One-Stop Machining Service

Clear Process, Stable Efficiency: From Design to Delivery.